Seal machine (commonly known as photosensitive seal engraving machine portrait seal engraving machine wedding seal engraving machine) photosensitive seal, as the latest seal in the world, has been rapidly promoted in China and has become an upgraded product of the seal industry in China due to its simple and fast production, clear seal, long service life and strong applicability.

Introduction to Seal Machine

With the promulgation and implementation of the Ministry of Public Security standard GA241.9-2000, the photosensitive seal machine has been recognized as the preferred seal machine meeting the standard.

This product is convenient and fast to make (customers can make it immediately, and take it as soon as they want). It has been stamped 100000 times in a row, and the print surface does not shrink or deform. The print is clear and does not spread. The ink is durable and does not fade. It is continuously oiled and used continuously. 0.1mm anti-counterfeit stripe can be made.

Separate exposure box design, accurate alignment. Higher exposure efficiency, sufficient energy and lighter machine weight. The overall appearance of the machine is beautiful, and the operation is simple. All the seal pads are formed by one exposure, which is durable.

By 2018, the seal machine will be made of crystal glass with better light transmission performance!

Features of seal machine

Smaller volume, lighter weight, strong energy and better effect, especially suitable for foreign trade export

Special high-performance photosensitive lamp is used, with longer service life, adjustable exposure energy and better exposure uniformity

One time forming, higher definition and better imaging quality

Super large window technology can solve the problem of large size seals, and multiple seals can be exposed at the same time

Child protection device, sealed for protection, does not affect eyes and does not cause any harm to human body

Fast production speed, high precision, stable product performance, high quality, zero failure

It has the advantages of simple and easy to master, low cost, high efficiency, etc

The advanced print pad clamp box design can well compress the seal pad

Characteristics of photosensitive seal

As the latest seal in the world, photosensitive seal has been rapidly promoted in China and has become an upgraded product of the seal industry in China due to its simple and fast production, clear seal, long service life and strong applicability

Photosensitive machine features

The basic principle of the photosensitive (portrait) seal machine is to use the photosensitivity of special materials to form an impermeable membrane on the surface of the seal where no imprint is needed, so as to achieve the effect of the seal The machine is simple to operate, convenient to use, small in size, and free of pollutants during the seal making process. Therefore, using photosensitive seals to make seals is fast.

Fundamentals

The basic principle of the photosensitive seal machine is to use the photosensitivity of special materials to form an impermeable membrane on the surface of the seal where no impression is needed, so as to achieve the effect of the seal. Therefore, using photosensitive seals to make seals is fast. The photosensitive seal machine does not need a printing pad and can be repeatedly oiled; The printing ink is nonproliferable, fadeless, and ready to print and dry; The seal shall be clear and free from deformation and sealing pressure; Service life of more than 100000 times; Conforming to the requirements of Seal Public Security Management Information System, it is really the best anti-counterfeiting; It can be stamped on plastic, copper paper, glass or metal.

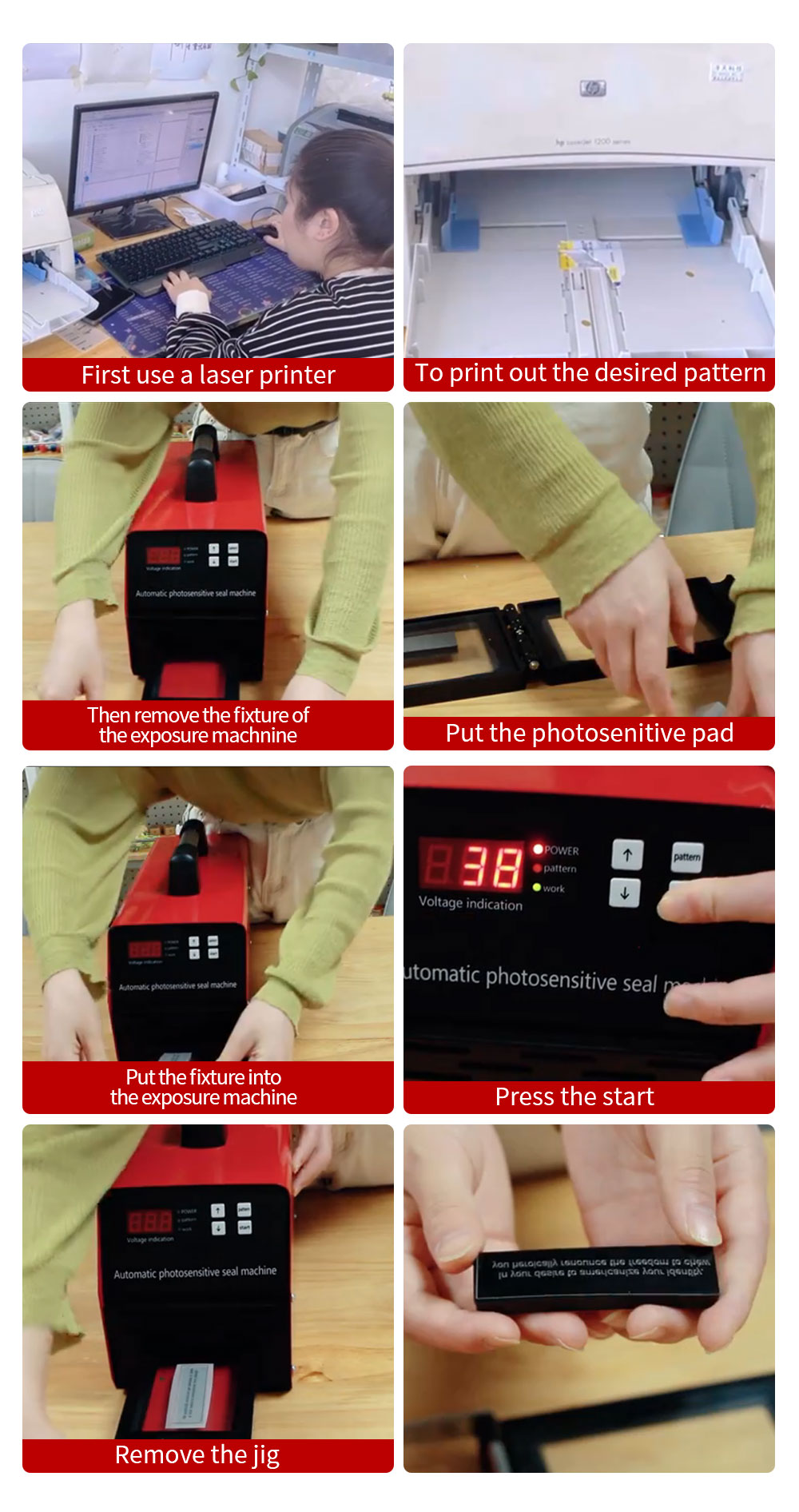

Production process

1) After the acquired portrait is processed by graphics software (such as photoshop, CroelDRAW, etc.) in the computer, the produced portrait or cartoon, and personalized picture sample are printed on sulfuric acid paper with a laser printer. Make sure the picture quality is clear, the outline is clear, and the contrast is good.

2) The transparent exposure film shall be covered according to the specification of the sample, and its size shall be subject to the full coverage of the sample.

3) The sequence and orientation of the printing sample, exposure film and photosensitive seal pad are as follows: the printing sample is at the bottom layer, close to the glass plate of the photosensitive machine, the printing side is up, the middle layer is the exposure film, and the third layer is the seal pad. The three shall be in smooth and close contact in turn, and there shall be no gap folds in the middle. Cover the light shield of the photosensitive machine, and pull the handle to compress it.

4) Connect the power and turn on the power switch, and the photosensitive device starts charging.

5) There are many kinds of photosensitive seal pads, and different seal pads need different exposure energy. In order to accurately expose all photosensitive seal pads, this machine adopts the exposure mode that can display free random exposure according to the voltmeter. The exposure voltage ranges from 240V to 300V, which can be exposed. (In the initial use, it is recommended that the user first test the best exposure voltage value suitable for this chapter pad with leftover materials. For example, for some domestic photosensitive pads, the exposure voltage value is 240V+5% for sulfuric acid paper print and 220V+5% for film print). When the charge indication of the photosensitive machine reaches the required exposure voltage of the chapter pad, turn off the power, press the trigger button to complete the exposure.

6) Loosen the pressing handle, open the light shield, take out the exposed photosensitive pad, and remove the film.

7) Put the exposed seal pad into the corresponding seal shell, and use AB glue to make the seal pad seal shell firm.

8) Inject a standard amount of ink according to the seal specification. After the ink is absorbed and distributed evenly, it can be delivered to the customer for use.

Name: Debin Zhou

Mobile:+86 15026466402

Tel:+86 15026466402

Whatsapp:+86 15026466402

Email:ayan@ayanstamps.com

Add:1116, Building E, Greenland Center, Baohe District, Hefei, Anhui 230000, China