The laser engraving machine can improve the efficiency of engraving, make the surface of the engraved place smooth and round, quickly reduce the temperature of the engraved non-metallic material, and reduce the deformation and internal stress of the engraved object; According to the different laser light sources, it can be divided into CO2 non-metallic laser engraving machine and optical fiber metal engraving machine. CO2 non-metallic laser engraving machines generally use glass laser tubes in China, and some high-end laser engraving machines use CO2 metal RF tubes.

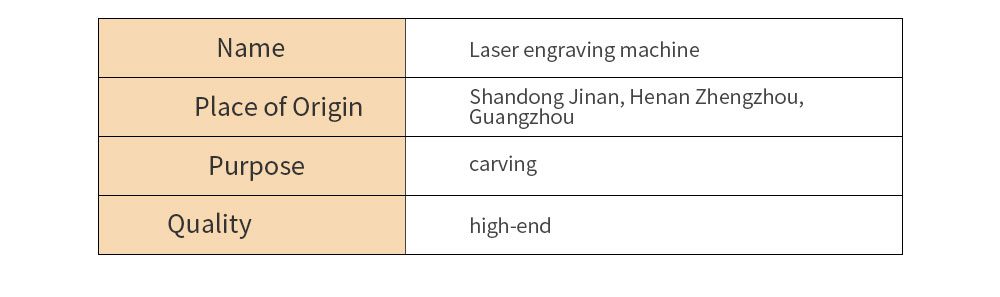

Brief introduction

Laser engraving machine, as the name suggests, is both an advanced equipment that uses a laser to engrave the material that needs to be engraved. Laser engraving machine is different from mechanical engraving machine and other traditional manual engraving methods, mechanical engraving machine is the use of mechanical means, such as diamond and other extremely hard materials to engrave other things.

The laser engraving machine uses the thermal energy of the laser to engrave the material, and the laser in the laser engraving machine is its core. Generally speaking, laser engraving machines are used more extensively, and the engraving accuracy is higher and the engraving speed is faster. And compared with the traditional manual engraving method, laser engraving can also make the engraving effect very delicate, no less than the process level of hand engraving. It is precisely because laser engraving machines have so many advantages, so now the application of laser engraving machines has gradually replaced the traditional engraving equipment and methods. It became the main engraving equipment.

classify

Laser engraving machines can be roughly divided into: non-metallic laser engraving machines and metal laser engraving machines.

Non-metallic engraving machine can be divided into: CO2 glass tube laser engraving machine and metal RF tube laser engraving machine.

Metal engraving machine can be divided into: metal fiber marking machine and metal fiber laser engraving machine.

Non-metallic engraving machine

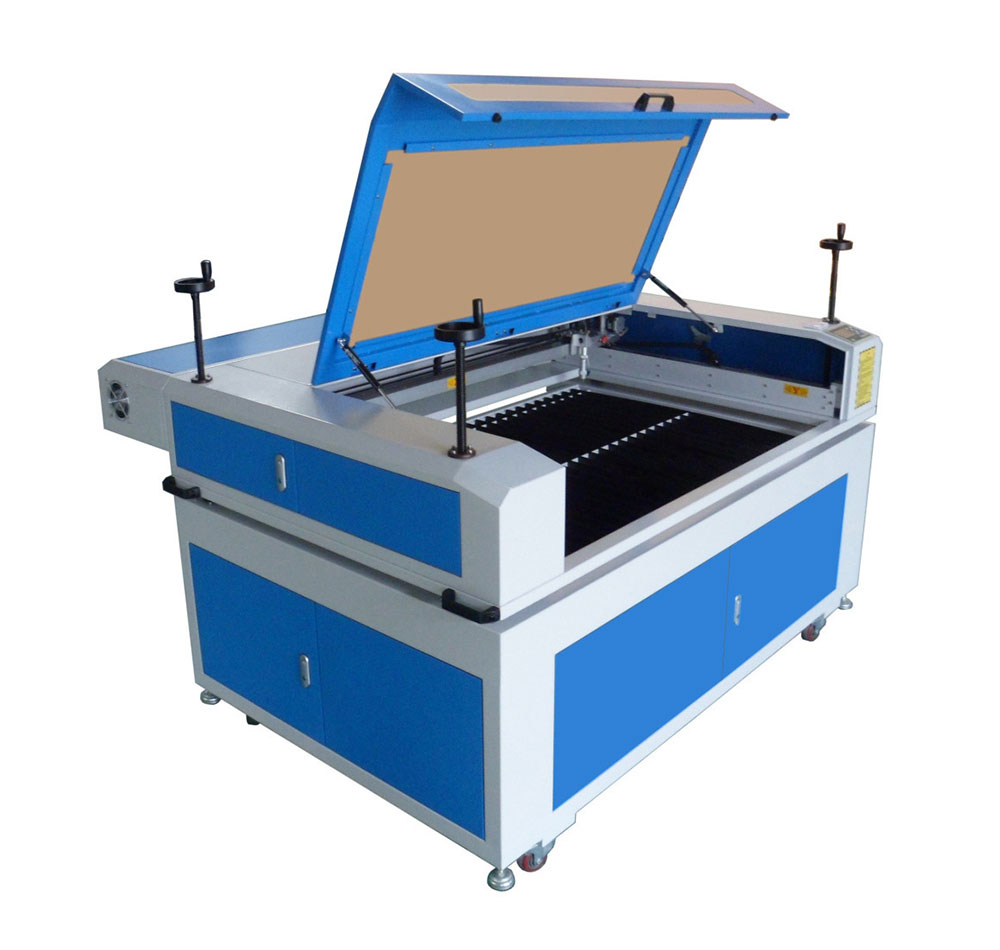

Laser engraving machine

Non-metallic engraving machine

Non-metallic engraving machine (4 photos)

Product Description:

With the increasing complexity of cutting and engraving process, traditional manual processing and mechanical processing are restricted by equipment and technology, and the accuracy of the processed object is low and affects the quality of the product to a certain extent, and even affects the economic benefits.

According to the energy high density of the laser, strong operability, wide range of processing materials, smooth cutting edge without burrs, no polishing, no noise, no dust, fast processing speed, high precision, less waste, high efficiency, it is the best choice for various industries to have and replace generations.

Functions, product features:

Imported linear guide rail and high-speed stepper motor and driver make the cutting effect edge smooth and corrugation-free;

The integrated frame structure design is adopted to make the machine run stably and without noise;

Simple operation, arbitrary engraving sequence, processing level, partial or full one-time output laser power, speed, focal length adjustment flexibility;

Open software interface, compatible with Autocad, Coreldraw, Wentai engraving, Photoshop and other vector graphics design software;

Equipped with water breaker protector, better protection of the laser, extend the life of the laser, optional foot switch, make your operation more simple and fast.

Exquisite design; Super strength steel plate, industrial grade; Effectively ensure the smooth operation and life of the equipment;

Double-rail operation; belt drive; You can choose to configure honeycomb/grid/flat/lift;

Patented technology: unique upper and lower exhaust smoke and dust removal system; Blow protection; Engraving cutting materials.

It can be laser processed on non-metallic materials such as bamboo wood, crystal, horn, paper plate, plexiglass, marble, cloth, leather, rubber, plastic, etc. Clothing, embroidery, cloth toys, home decoration fabrics, handbags, gloves, leather cutting and surface carving in the toy industry. Precision cutting of acrylic sheets, medium density decorative boards and other non-metallic sheets in the handicrafts, models, advertising, decoration, electrical appliances, plastic industries.

Relevant parameters

Laser type: carbon dioxide sealed glass laser, water cooled;

Effective format: 1200×900 mm

Cooling method: water cooling

Engraving scanning speed: 0-60000 mm/min

Cutting speed: 0-30000mm/min

Laser energy control: 1-100% software setting

Minimum formed text: Chinese characters 2.0×2.0 mm, English 1.0×1.0 mm

Positioning accuracy: ≤±0.01 mm

Supported graphic formats: DST, PLT, BMP, DXF, AI

SUPPORTED SOFTWARE: TAJIMA EMBROIDERY SOFTWARE, CORELDRAW, PHOTOSHOP, AUTOCAD, VARIOUS GARMENT CAD SOFTWARE

Separation cut: Yes

Power supply: 220V

Working temperature: 0-45°

Operating humidity: 5-95%

Machine size/weight: 1860*1410*1090400KG

Part of the sample made by the machine

Part of the samples made by the machine

Metal engraving machine

Laser set many years of production and use experience, the latest design concept, equipped with domestic and foreign advanced laser components, launched a new generation of large-format, multi-functional laser processing system, simple operation, convenient maintenance, production safety protection is more perfect. It is characterized by:

The open working platform facilitates the placement of processing materials and can work with the assembly line to meet the processing of large-format materials. At the same time, with large-size honeycomb platform, knife strip platform and local lifting platform, this laser machine is not only suitable for large-scale on-site processing industries, such as: footwear, clothing, advertising, etc., but also to meet the needs of small industries such as model industry, handicraft industry, bamboo products industry, etc. With automatic focus, red light positioning and other functions, this machine is perfect and its function is brought to the extreme. Truly multi-functional, multi-purpose, time-saving and efficient. Its optical path part adopts hybrid optical path, and the light energy utilization rate is high; The optical path is fully enclosed and has strong safety performance. Its control system adopts unique intelligent prediction algorithm and improved control algorithm to ensure high-speed processing, smooth and efficient running speed, and real-time adjustment of laser energy, which greatly facilitates the operation of customers. And with a built-in 128M (up to 1G), it can store 99 files at the same time and support a permanent file storage area for saving power failure data. Thirdly, the automatic compensation function of high-power cutting energy greatly improves the cutting effect. In short, this model truly achieves a wide range of processed fabrics, smooth cuts without flashing, automatic closure, no deformation, graphics can be designed at will through the computer and other functions.

Application Industry:

Kitchenware metal sheet cutting, advertising words, large-format truncation, clothing proofing, leather industry, footwear industry, decoration industry, furniture industry, packaging and printing industry, model industry, craft gift industry, etc.

Applicable materials:

Metal sheet, acrylic, plexiglass, glass, cloth, leather, paper, bamboo and wood products, film, canvas, etc.

Technical parameters:

Laser power: 130W/150W

Laser type: CO2 sealed glass tube laser, water-cooled, 10.6um

Effective format: 1500mm×2500mm

Cooling method: water cooling

Engraving scanning speed: 0-60000mm/min

Machine example display

Machine example display

Maximum movement speed: 30000mm/min

Cutting speed: 0-1000mm/min

Laser energy control: 1-100% software setting

Minimum formed text: Chinese characters 2.0mm× 2.0mm English 1.0mm× 1.0mm

Maximum scanning accuracy: 2500DPI

Positioning accuracy: ≤±0.01mm

Supported graphic formats: DST, PLT, BMP, DXF, AI

SUPPORTED SOFTWARE: TAJIMA EMBROIDERY SOFTWARE, CORELDRAW, PHOTOSHOP, AUTOCAD, VARIOUS CLOTHING CAD

Applicable materials

Wood products, paper, leather, cloth, plexiglass, epoxy resin, acrylic, wool, plastic, rubber, tiles, marble, crystal, jade, bamboo products and other non-metallic materials.

Fault points

1. The fulcrum of the laser tube installation should be reasonable, the fulcrum should be 1/4 of the total length of the laser tube, otherwise the laser tube spot mode will deteriorate, and some work for a period of time the spot will become several points, resulting in the laser power decline can not meet the requirements, resulting in continuous tube replacement, carefully read the "Precautions for the use of laser tube".

2. The cooling system should be grounded, often clean the water tank and waterway, and the temperature control point of the refrigeration temperature control tank should be reasonable, otherwise the laser tube is easy to break and the condensation power is reduced, the cold water head of the tube falls off, the life is greatly shortened, and sometimes it cannot work, resulting in continuous tube replacement.

3. Water protection should be checked and cleaned frequently, cooling water often can not flush water protection float switch or water protection float switch does not reset, can not use short connection method to solve the urgent need. The cooling water quality should be good, the aluminum oxide of the water nozzle is too serious, and the dirt in the water pump and water pipe and water protection should be cleaned regularly after a period of use, otherwise the laser tube will burst or the cold water head will fall off.

4. The suction device should be checked and cleaned regularly to clean up the fan duct. Otherwise, a lot of smoke and dust cannot be discharged, seriously and quickly polluting the lens and laser tube, so that the mechanical and electronic components are easy to oxidize and cause poor contact.

5. Focusing mirror and reflector inspection, the frame will heat up after working for a while, and the surface of the lens will change color and rust; Peeling cracking belongs to the object to be replaced, especially many customers use air pumps and air compressors, so that water quickly accumulates on the focusing lens, so it is necessary to check the cleanliness and quality of the optical path system of the lens (laser tube outlet) on time.

6. The working environment of the machine can not be too bad, if the ambient temperature is higher than 30 degrees, below 18 degrees, there is too much dust, and the air pollution is serious, so that the machine is seriously damaged and the failure rate continues to rise; Electrical accessories are prone to problems in humid environments. Therefore, customers are specially reminded to improve the working environment and carry out frequent maintenance of the machine.

7. The power grid power should be matched. The power distribution and contact points of each part of the whole equipment should be good (fan, water cooler, laser machine, laser power supply, computer should be independently powered).

8. The working current of the laser tube should be reasonable, and it cannot work at 90-100 light intensity for a long time; It is necessary to rationalize the application of lasers and save laser energy; The optical path system should be cleaned correctly, otherwise the laser tube will be premature aging and rupture, so the working time of the laser machine should be adjusted to 50-60% and then adjust the working speed according to the material, so that the laser tube is in the best working state.

9. The bottom plate and the processed material should be flat, otherwise the focal length is inconsistent and some places cannot be cut, so that the light intensity will be increased, and the laser tube will also cause rapid aging.

Laser engraving machine accessories display

Laser engraving machine accessories display (4 photos)

10. The heat dissipation of the laser power supply should be smooth, otherwise once the working current is adjusted by more than 50%, the temperature will rise very high, which will increase the failure rate of the laser power supply. For example, the TM series machine can remove the side door and directly dissipate the heat emitted by the power supply.

Notes

1. When using the automatic focal length, pay attention to the automatic focus rod must be tightened, otherwise the work table will be jacked to the laser.

2. When the laser engraving machine is working, it is forbidden to open the cover.

3. Open the smoke exhaust and smoke blowing equipment during processing.

4. To process wood and paper, we must pay attention to the processing speed to avoid fire.

5. When the initial user performs irregular processing, the red light positioning is carried out first.

6. When processing thin wood boards and volatile materials, adjust the luffing water product by less than 1mm.

7. When cutting, use the workpiece frame to be more than 2 cm away from the worktable.

8. Clean reflective lenses and focal length lenses: pinch the reflective lenses with two fingers. The other hand holds the camera lens cleaning paper to clean the lens.

9. Usually when engraving vector files, the resolution should be higher, and when engraving point files, the resolution should be selected lower

Machine settings

Dot matrix engravingDotmatrix engraving resembles high-definition dot matrix printing. The laser head swings left and right, each time engraving a line composed of a series of points, and then the laser head moves up and down at the same time to engrave multiple lines, and finally forms a full-page image or text. Scanned graphics, text and vectorized graphics can be engraved using dot matrix engraving.

Vector cutting is different from dot matrix engraving, vector cutting is carried out on the outer contour line of the graphic text. We usually use this mode to perform penetration cutting on wood, acrylic, paper and other materials, and can also perform marking operations on a variety of material surfaces.

Engraving speed: Engraving speed refers to the speed at which the laser head moves, usually expressed in IPS (inches per second), high speed brings high production efficiency. Speed is also used to control the depth of the cut, and for a specific laser intensity, the slower the speed, the greater the depth of the cut or engraving. You can adjust the speed using the engraving machine panel or using the operating software of your computer. In the range of 1% to 100%, the adjustment is 1%. The motor's advanced motion control system allows you to engrave at high speeds and still get ultra-fine engraving quality.

Engraving intensity: Engraving intensity refers to the intensity of the laser light on the surface of the material. For a specific engraving speed, the greater the intensity, the greater the depth of the cut or engraving. You can adjust the intensity using the engraving machine panel or using the operating software of your computer. In the range of 1% to 100%, the adjustment is 1%. The greater the intensity, the smaller the speed. The deeper the cut is also deeper.

Spot size: The spot size of the laser beam can be adjusted using lenses with different focal lengths. Lenses with small spots are used for high-resolution engraving. Lenses with large spots are used for lower resolution engraving, but for vector cutting, it is the best choice.

Upper processing

The advantage of laser processing is that it can quickly engrave and hollow out various patterns on the surface of various upper materials, because laser processing is a non-contact processing method, so it will not cause any external deformation on the upper. It has many advantages such as high engraving accuracy, hollowing without burrs, and can process any shape.

However, it is precisely because the laser has the characteristics of high-density energy, so when laser processing cutting or laser cutting shoe upper materials, especially light materials (such as white beige, etc.), or special materials (such as mirror materials, etc.), the surface or interior of the upper is prone to burnt or yellowing phenomenon.

In order to prevent this phenomenon, in the production and processing, it is necessary to carry out certain protection treatment on the surface of the upper, the usual methods are:

First, stick the protective film, must be flat, tight, no bubbles.

Second, soak some uppers, this method is suitable for some materials.

Third, adjust the laser processing parameters and adopt the method of multi-frequency and small firepower.

These three points are used to prevent the high temperature generated by laser processing cutting or laser hollowing out the upper, burning the surface or inside of the upper. Experience gained in practice, welcome the majority of users to divide the valuable experience of laser processing!

Name: Debin Zhou

Mobile:+86 15026466402

Tel:+86 15026466402

Whatsapp:+86 15026466402

Email:ayan@ayanstamps.com

Add:1116, Building E, Greenland Center, Baohe District, Hefei, Anhui 230000, China