Engraving is a combination of drilling and milling processing from the processing principle, and the various data input modes of the engraving machine are comfortable as needed. Computer engraving machines have two categories: laser engraving and mechanical engraving, both of which have high power and low power. Because the application range of engraving machines is very wide, it is necessary to understand the most suitable application range of various engraving machines. The low-power is only suitable for two-color plates, architectural models, small signs, three-dimensional crafts, etc., and the power of carving jade, metal, etc. needs to be more than 1500W. High-power engraving machine can do things with low-power engraving machine. It is most suitable for large cutting, relief, and carving.

Technical introduction

In CNC machine tools, the electric spindle usually adopts the frequency conversion speed regulation method. There are mainly three control modes: ordinary frequency conversion drive and control, vector control drive drive and direct torque control.

Ordinary frequency conversion is scalar drive and control, and its drive control characteristics are constant torque drive, and the output power is proportional to the speed. The dynamic performance of ordinary frequency conversion control is not ideal, the control performance is poor at low speed, the output power is not stable enough, and it does not have the C-axis function. But the price is cheap, the structure is simple, generally used in grinding machines and ordinary high-speed milling machines.

Vector control technology imitates the control of DC motor, with rotor field orientation, using vector transformation method to achieve drive and control, with good dynamic performance. The vector control drive has a large torque value at the beginning of starting, coupled with the simple structure of the electric spindle itself and the inertia is very small, so the starting acceleration is large, and the allowable limit speed can be reached instantaneously after starting. There are two kinds of such drives, open loop and closed loop, the latter can realize position and speed feedback, not only has better dynamic performance, but also can realize C-axis function; The former has slightly worse dynamic performance and does not have C-axis function, but the price is cheaper.

Direct torque control is another new type of high-performance AC speed regulation technology developed after vector control technology, its control idea is novel, the system structure is simple and clear, more suitable for the drive of high-speed electric spindle, more can meet the requirements of high speed spindle high speed, wide speed regulation range, high-speed instant stop dynamic characteristics and static characteristics, has become a hot technology in the field of AC transmission.

Scope of application:

Granite, marble, bluestone, sandstone and other stone carvings

Hard stones such as granite can be carved in layers up to 5mm

Marble, bluestone, etc. can be carved up to 5mm at a time

System Classification Edit Announcement

1. Stepper drive + stepper motor

The stepper system is currently the most used drive system on the market, and the most popular is the three-phase hybrid stepper motor, accounting for more than 90% of the market share, the reason is that the price is cheap, and the effect is good with the Lesser high subdivision drive. However, the defects are also obvious, such as: resonance, noise, speed increase, torque decrease, long-term work is easy to lose steps, motor temperature rise is too high, etc.

2. Hybrid servo drive + motor

The use of hybrid servo in China has not been popularized, there are many reasons, there are not many manufacturers of hybrid servo abroad, and the price does not have a very big advantage compared with AC servo, and can only be used in some special industries. Improvements include: improved high-speed performance, reduced heat generation, and reduced resonance.

3. AC servo drive + AC servo motor

AC servo in the use of engraving machine is still relatively small, the main reason is that the price is relatively high, in addition, the application of AC servo for the structure of the machine tool, electrical appliances, control system, transmission system have certain requirements, just like the barrel principle, the shortest board determines the amount of water in the barrel, because some AC servo is generally used in high-end models. AC servo has: fast response, large torque, high speed, high precision, less heat, continuous long-term work, complete alarm system, etc. Disadvantages: Different equipment should use different servo parameters, and the adjustment parameters require a high level of technical engineers.

Apply classification

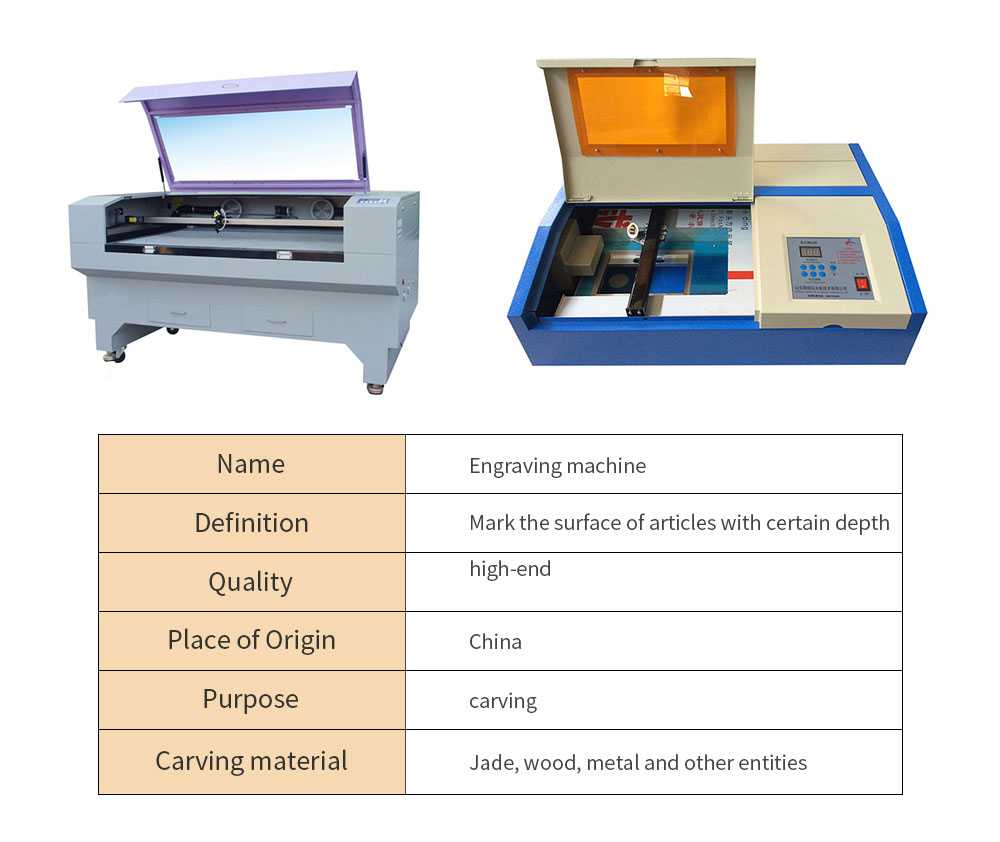

Computer engraving machines have two categories: laser engraving and mechanical engraving, both of which have high power and low power. Because the application range of engraving machines is very extensive, it is necessary to understand the most suitable application range of various engraving machines: 1. Badge: low-power laser engraving machine (stamping machine), high-power or low-power computer engraving machine; 2. Architectural model: large and small power computer engraving machine; 3. Metal (mold, seal, etc.) processing: large and small power computer engraving machine (high power saves time due to more cutting volume each time); 4. Crystal word production: high-power laser engraving machine (above 50W), high-power mechanical engraving machine; 5. Wood, plexiglass, artificial stone and other signage production: high-power mechanical engraving machine; 6. Display and exhibition model making: high-power, large-format mechanical engraving machine; 7. Ceramics, mold blanks, jade, handicrafts, ornaments, pendants, electronic fixtures, prototype carving: high-power computer engraving machine.

Main classifications

Woodworking engraving machine

Tombstone engraving machine

Laser engraving machine

Advertising engraving machine

Jade carving machine

Stone engraving machine

Cylindrical engraving machine

Mold engraving machine

Micro engraving machine

PCB circuit board engraving machine

Metal engraving machine

Glass engraving machine

Mold engraving machine

Main applications

Advertising industry, craft industry, mold industry, electronics industry, construction industry, printing and packaging industry, wood industry, decoration industry, tombstone industry, crystal products industry, etc.

Engraving consumables

Acrylic organic board, PVC board, hibiscus board, two-color board, woodworking board, MDF, marble, fireproof board, rubber sheet, glass, crystal, etc.

Business objects

Advertising companies, decoration companies, hotels, guesthouses, shopping malls, schools, hospitals, office buildings, entertainment venues, bathing centers, groups, enterprises, administrative agencies, etc.

Daily maintenance

The continuous running time is less than 10 hours a day, to ensure the cleaning of the cooling water and the normal operation of the water pump, never make the water spindle motor water shortage phenomenon, regularly replace the cooling water to prevent the water temperature from being too high. In winter, if the working environment temperature is too low, you can replace the water in the tank with antifreeze.

After each use of the machine, pay attention to cleaning, be sure to clean the dust on the platform and transmission system, and lubricate and oil the transmission system (X, Y, Z three axes) regularly (weekly). (Note: X, Y, Z three-axis light rod with oil for maintenance; the screw part with high-speed butter; In winter, if the working environment temperature is too low, the PRTT ball screw and light rod (square rail or round guide rail) part should be rinsed and cleaned with gasoline first, and then add oil, otherwise it will cause excessive resistance of the machine transmission part and cause the machine to be misaligned. )

When maintaining and inspecting electrical appliances, be sure to cut off the power supply, and only after the monitor has no display and the main circuit power indicator is turned off.

The engraving machine is used for about three months to check the fasteners, and the connecting screws on both sides of the gantry, the fastening screws of the lead screw nuts, and the fastening screws of the motors on both sides are tightened.

Failure analysis

Alarm failure

Overtravel alarm, indicating that the machine has reached the limit position during operation, please check as follows:

Whether the designed graphic size is outside the processing range.

Check whether the connecting wire between the machine motor shaft and the lead screw is loose, and if so, tighten the screws.

Whether the machine and computer are properly grounded.

Whether the current coordinate value is outside the range of soft limit values.

Alarm and dismissal

When overtraveling, all motion axes are automatically set in the jog state, as long as the manual arrow key is held down all the time, the connected motion state is restored at any time when the machine leaves the limit position (i.e. away from the overtravel point switch).

When moving the table, pay attention to the direction of movement and must be far away from the limit position.

The soft limit alarm needs to clear XYZ to zero in the coordinate setting

Non-alarm fault

1. If the repeated machining accuracy is not enough, check according to the second item of Article 1.

2. The computer is running, the machine does not move, check whether the connection between the computer control card and the electrical box is loose, if so, plug it in tightly, and tighten the fixing screw.

3. The machine cannot find a signal when returning to the origin of the machine, check according to Article 2. The proximity switch fails at the mechanical origin.

Output failure

1. No output, please check whether the computer and control box are well connected.

2. Open the settings of the engraving manager to check whether the space is full, and delete the unused files in the manager.

3. Whether the signal line wiring is loose, carefully check whether each line is connected.

Engraving failure

1. Whether the screws in each part are loose.

2. Check whether the path you are dealing with is correct.

3. Whether the file is too large and causes computer processing errors.

4. Increase or decrease the spindle speed to adapt to different materials (generally 8000-24000)

5. Loosen the knife chuck, turn the knife in one direction and clamp it, and put the knife straight, so as not to engrave the object unclean.

6. Check whether the knife is damaged, replace it with a new knife, and re-engrave.

Performance characteristics

Equipped with imported double nut lead screw.

The use of breakpoint memory method ensures that it can be processed in case of accident (broken knife) or alternate day.

Unique way to preserve multiple workpiece processing origins.

The high-power cut not only makes the engraving fine and free of serrations, but also makes the underside smooth and contoured.

This machine is very suitable for architectural model, sign industry, school, enterprise and institution use

FOR GLASS ENGRAVING, THE ENGRAVING THICKNESS IS ABOVE 5MM

Scope of use

woodworker

Woodworking engraving machine can be applied to furniture industry, furniture decoration industry, woodworking decoration industry, musical instrument industry, wooden handicraft industry, this machine is suitable for large-area plate plane carving, solid wood furniture carving, solid wood art mural carving, solid wood carving, MDF paint-free door carving, kitchen window door carving. It is a replacement product in the furniture decoration industry.

Wooden industrial products: such as sewing machine countertops, electrical cabinet panels, sporting goods equipment, etc.

Mold industry: can engrave all kinds of molds, wood molds, aviation wood molds, propellers, automotive foam molds.

Musical instrument industry: can engrave three-dimensional curved surfaces of musical instruments, and cut appearance.

ad

With people's understanding and mastery of advertising engraving machine, the application scope and application level will gradually improve, such as advertising industry, seal industry, craft gift industry, art model industry, wood processing industry, mold industry and so on. The materials that can be processed include acrylic, two-color board, PVC, ABS board, stone, imitation stone, metal, aluminum-plastic board and other materials.

Advertising industry: engraving, cutting all kinds of signs, seat signs, marble, copper, character molds, fonts, all kinds of signs, trademarks and other metal materials.

Handicraft industry: handicrafts, souvenirs engraved with all kinds of text, graphics, iron art carvings, dials.

Mold processing: architectural model, physical model, hot stamping mold, motor, high frequency mold, micro injection mold, shoe mold, badge, embossing mold, biscuit, chocolate, candy mold.

Seal industry: Stamps can be easily engraved on horns, plastics, organic boards, wood, storage pads and other materials.

Two-color plate carving, stone engraving machine use and applicable materials:

1. Mainly used for large-scale blister word cutting. Plexiglass engraving cutting, signage engraving, crystal, trophy engraving, authorization plate engraving, etc.

2. Handicraft industry: wood, bamboo pieces, ivory, bones, leather, marble, shells and other materials carved exquisite patterns and words. Cutting, carving and hollowing and other process processing. Cutting and carving in garments, underwear, home accessories, gloves, handbags, shoes, hats, toys and car flower industries.

3. Leather garment processing industry: complex text and graphic engraving on genuine leather, synthetic leather, artificial leather, cloth and fur.

4. Model industry: making sand table architectural models and aircraft models. Multilayer board cutting, etc., ABC plate cutting.

5. Packaging industry: engraving and printing rubber sheet, plastic plate, double-layer plate, knife die cutting knife plate, etc.

6. Product identification industry: equipment nameplate, product anti-counterfeiting marking, etc.

How it works

Computer engraving machine is composed of three parts: computer, engraving machine controller, and engraving machine host. Working principle: It is designed and typeset by the special engraving software configured in the computer, and the computer automatically transmits the design and typesetting information to the engraving machine controller, and then the controller converts this information into a signal (pulse train) with power that can drive a stepper motor or servo motor, and controls the engraving machine host to generate X, Y, Z three-axis engraving tool path base diameter. At the same time, the high-speed rotating engraving head on the engraving machine, through the tools configured according to the processing material, the processing material fixed on the host workbench can be cut, and various flat or three-dimensional relief graphics and text designed in the computer can be carved to realize the automatic operation of engraving.

Name: Debin Zhou

Mobile:+86 15026466402

Tel:+86 15026466402

Whatsapp:+86 15026466402

Email:ayan@ayanstamps.com

Add:1116, Building E, Greenland Center, Baohe District, Hefei, Anhui 230000, China